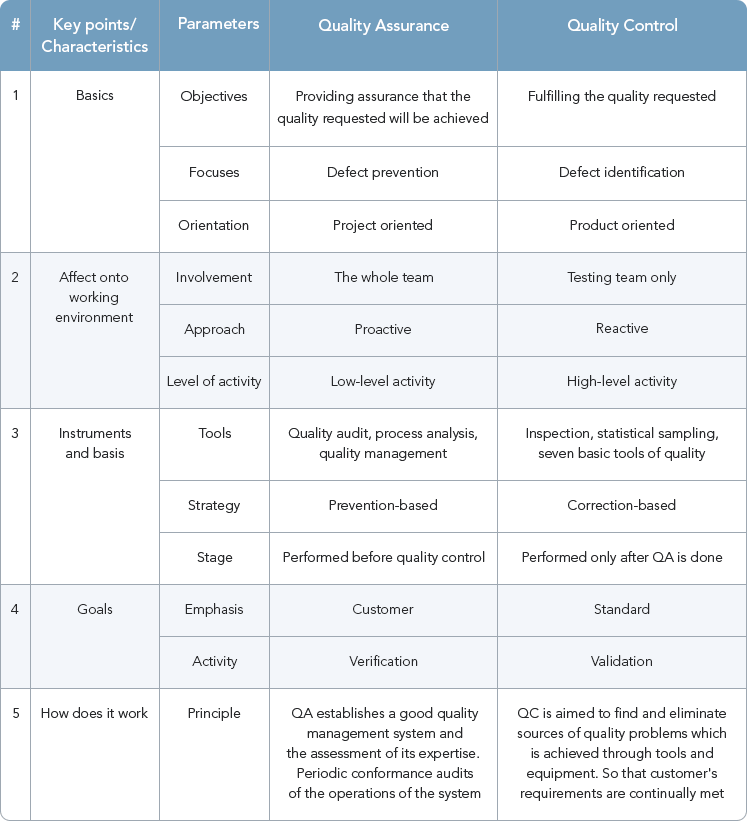

Quality assurance designs a process so that the product created by this process is defect free while quality control checks the product when producing it to prevent a defective product from reaching the market. Quality assurance reduces waste as faulty products are identified early in the production process whereas quality control will save the company time and money as less checks are required during the.

Advantages Of Quality Control And Assurance. Having total equality through quality assurance will improve the quality of work while raising morale in a team. In order to enhance client satisfaction during a construction project the project must meet the expected quality. An integrated system of management procedures and activities used to verify that the quality control system is operating within acceptable limits and to. Quality data and deliverables that can be used to support specific decisions involving nonpoint source pollution.

Ferrotec Nord Provides Module Quality Control At All Production Stages Regulated By The Quality Assurance Program To Focus Technology From pinterest.com

Ferrotec Nord Provides Module Quality Control At All Production Stages Regulated By The Quality Assurance Program To Focus Technology From pinterest.com

When it comes to our focus we understand that quality control is a product-oriented process. There are many differences between quality control and quality assurance. In quality assurance a constant effort is made to enhance the quality practices in the organization. Quality assurance designs a process so that the product created by this process is defect free while quality control checks the product when producing it to prevent a defective product from reaching the market. The Benefits of Quality Assurance and Quality Control It gives you a high quality output. Customer Gains Customer gains is another one of the Benefits Of Quality Assurance.

Therefore continuous improvements are expected in quality functions in the company.

When it comes to quality. These two processes normally require a lot of manpower and labor hours but can be automated through software systems like SAP Business One which has quality assurance built-in. Quality Control QC refers to quality related activities associated with the creation of project deliverables. It is not disruptive to production- workers continue producing inspectors do the checking.

Source: blog.railwaymen.org

Source: blog.railwaymen.org

Quality Control QC refers to quality related activities associated with the creation of project deliverables. Importance of Quality Control and Quality Assurance Procedures. In order to enhance client satisfaction during a construction project the project must meet the expected quality. Examples of quality assurance include process checklists project audits and methodology and standards development. Quality assurance and quality control in manufacturing saves time money and resources while ensuring a product of the highest quality is always the end result.

Source: pinterest.com

Source: pinterest.com

Therefore continuous improvements are expected in quality functions in the company. In quality assurance a constant effort is made to enhance the quality practices in the organization. Benefits of Quality Assurance and Quality Control. Therefore continuous improvements are expected in quality functions in the company. Responsibilities of Quality Assurance Department.

Source: pinterest.com

Source: pinterest.com

It is not disruptive to production- workers continue producing inspectors do the checking. Having total equality through quality assurance will improve the quality of work while raising morale in a team. In quality assurance a constant effort is made to enhance the quality practices in the organization. Customer Gains Customer gains is another one of the Benefits Of Quality Assurance. The QA department is responsible for ensuring that the quality policies adopted by a company are followed.

Source: pinterest.com

Source: pinterest.com

The Benefits of Quality Assurance and Quality Control It gives you a high quality output. Reduce rework and enable efficient use of resources. Quality assurance and quality control in manufacturing saves time money and resources while ensuring a product of the highest quality is always the end result. It is defined by ISO 9000 as the part of quality management focused on providing confidence that quality requirements will be fulfilled. Quality assurance reduces waste as faulty products are identified early in the production process whereas quality control will save the company time and money as less checks are required during the.

Source: pinterest.com

Source: pinterest.com

An integrated system of management procedures and activities used to verify that the quality control system is operating within acceptable limits and to. It brings customer satisfaction which affects your brand and helps you grow your business. This expected quality can be ensured through quality assurance and quality control activities. It increases the efficiency of operations. Examples of quality assurance include process checklists project audits and methodology and standards development.

Source: voymedia.com

Source: voymedia.com

These two processes normally require a lot of manpower and labor hours but can be automated through software systems like SAP Business One which has quality assurance built-in. Responsibilities of Quality Assurance Department. Reduce rework and enable efficient use of resources. It increases the efficiency of operations. Increase the efficiency of the processes.

Source: pinterest.com

Source: pinterest.com

When it comes to our focus we understand that quality control is a product-oriented process. As with any quality system the business may benefit from an improved reputationfor quality and and this may increase sales. These two processes normally require a lot of manpower and labor hours but can be automated through software systems like SAP Business One which has quality assurance built-in. Quality assurance and quality control in manufacturing saves time money and resources while ensuring a product of the highest quality is always the end result. Therefore continuous improvements are expected in quality functions in the company.

Source: pinterest.com

Source: pinterest.com

As with any quality system the business may benefit from an improved reputationfor quality and and this may increase sales. The QA department is responsible for ensuring that the quality policies adopted by a company are followed. An integrated system of management procedures and activities used to verify that the quality control system is operating within acceptable limits and to. An alternate definition is the operational techniques and activities used to fulfill requirements for quality. Increase the efficiency of the processes.

Source: javabydeveloper.com

Source: javabydeveloper.com

Benefits of Quality Assurance and Quality Control. The QA department is responsible for ensuring that the quality policies adopted by a company are followed. Whereas quality control focuses on identifying defects quality assurance QA focuses on the prevention of defects. Quality data and deliverables that can be used to support specific decisions involving nonpoint source pollution. While quality assurance relates to how a process is performed or how a product is made quality control is more the inspection aspect of quality management.

Source: pinterest.com

Source: pinterest.com

Quality control is usually the responsibility of a specific team that tests the product for defects. Quality assurance and quality control in manufacturing saves time money and resources while ensuring a product of the highest quality is always the end result. Examples of quality assurance include process checklists project audits and methodology and standards development. Quality assurance is a process-based and quality control is a product-based. As with any quality system the business may benefit from an improved reputationfor quality and and this may increase sales.

Source: blog.railwaymen.org

Source: blog.railwaymen.org

Quality Control QC refers to quality related activities associated with the creation of project deliverables. These two processes normally require a lot of manpower and labor hours but can be automated through software systems like SAP Business One which has quality assurance built-in. Quality assurance and quality control in manufacturing saves time money and resources while ensuring a product of the highest quality is always the end result. 511 Definitions of Quality Assurance and Quality Control. When it comes to our focus we understand that quality control is a product-oriented process.

Source: pinterest.com

Source: pinterest.com

There are many differences between quality control and quality assurance. Quality control is usually the responsibility of a specific team that tests the product for defects. Therefore continuous improvements are expected in quality functions in the company. Quality assurance reduces waste as faulty products are identified early in the production process whereas quality control will save the company time and money as less checks are required during the. Whereas quality control focuses on identifying defects quality assurance QA focuses on the prevention of defects.

Source: pinterest.com

Source: pinterest.com

An alternate definition is the operational techniques and activities used to fulfill requirements for quality. The Benefits of Quality Assurance and Quality Control It gives you a high quality output. Therefore continuous improvements are expected in quality functions in the company. Increase the efficiency of the processes. It increases the efficiency of operations.

Source: sam-solutions.com

Source: sam-solutions.com

In order to enhance client satisfaction during a construction project the project must meet the expected quality. Having total equality through quality assurance will improve the quality of work while raising morale in a team. There are many differences between quality control and quality assurance. Quality Control QC refers to quality related activities associated with the creation of project deliverables. It is not disruptive to production- workers continue producing inspectors do the checking.

Source: pinterest.com

Source: pinterest.com

Quality assurance designs a process so that the product created by this process is defect free while quality control checks the product when producing it to prevent a defective product from reaching the market. Quality assurance reduces waste as faulty products are identified early in the production process whereas quality control will save the company time and money as less checks are required during the. There are many differences between quality control and quality assurance. An integrated system of management procedures and activities used to verify that the quality control system is operating within acceptable limits and to. In quality assurance a constant effort is made to enhance the quality practices in the organization.

Source: pmp-practitioners.com

Source: pmp-practitioners.com

When it comes to quality. Customer Gains Customer gains is another one of the Benefits Of Quality Assurance. When it comes to quality. Quality assurance is a process-based and quality control is a product-based. Whereas quality control focuses on identifying defects quality assurance QA focuses on the prevention of defects.

Source: pinterest.com

Source: pinterest.com

It increases the efficiency of operations. It increases the efficiency of operations. As with any quality system the business may benefit from an improved reputationfor quality and and this may increase sales. It is not disruptive to production- workers continue producing inspectors do the checking. Having total equality through quality assurance will improve the quality of work while raising morale in a team.

Source: pinterest.com

Source: pinterest.com

Quality assurance designs a process so that the product created by this process is defect free while quality control checks the product when producing it to prevent a defective product from reaching the market. It is not disruptive to production- workers continue producing inspectors do the checking. Responsibilities of Quality Assurance Department. It can help to prevent faulty goods and servies being sold. As with any quality system the business may benefit from an improved reputationfor quality and and this may increase sales.