These costs are huge running at 20 - 40 of sales3 Many of these costs can be significantly reduced or completely avoided. When implement and tracking a cost of quality system within a company management typically focuses on internal and external failure costs.

Cost Of Quality Assurance. There are few studies where the internal cost of implementing an ISO 9001 management system have been carefully compared against the cost of the consultant. Prevention Appraisal Internal Failure External Failure. Quality Assurance is popularly known as QA Testing. Marys spent 06 of its operating budget on its quality assurance function.

Pin On Best Of Flevy Com From pinterest.com

Pin On Best Of Flevy Com From pinterest.com

One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. These costs are huge running at 20 - 40 of sales3 Many of these costs can be significantly reduced or completely avoided. Cost of Quality COQ Cost of quality COQ is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality that appraise the quality of the organizations products or services and that result from internal and external failures. The cost of quality not only includes factory. Management studies the costs due to defects and not the cost to prevent the defects. The Cost of Quality can be represented by the sum of two factors.

Quality assurance focuses on improving the software development process and making it efficient and effective as per the quality standards defined for software products.

1 877 238 5855. Cost of Quality COQ Cost of quality COQ is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality that appraise the quality of the organizations products or services and that result from internal and external failures. This is very important as the internal costs are often ignored probably because they are difficult to quantify. Costs and Cost Analysis Hospital Bed Capacity 300 to 499 Hospitals Community economics.

Source: pinterest.com

Source: pinterest.com

There are few studies where the internal cost of implementing an ISO 9001 management system have been carefully compared against the cost of the consultant. Definition of quality cost as those which are incurred from investing in preventing noncompliance with requirements evaluating compliance with the requirements of a product or service and failure to meet requirements. In this site the term quality costs means the cost of poor quality. Marys spent 06 of its operating budget on its quality assurance function. Management studies the costs due to defects and not the cost to prevent the defects.

Source: pinterest.com

Source: pinterest.com

These costs are huge running at 20 - 40 of sales3 Many of these costs can be significantly reduced or completely avoided. One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. Prevention Appraisal Internal Failure External Failure. He famously said Do things right in the first place and you wont have to pay to fix them. Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses.

Source: no.pinterest.com

Source: no.pinterest.com

One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. Phil Crosby one of the fathers of quality spoke of and called his book Quality is Free. This is very important as the internal costs are often ignored probably because they are difficult to quantify. In addition the medical staff and others contributed 1013 hr of time to the quality assurance program. The total cost of quality is 80 man-days while the failure cost would be reduced by 250 to 350 man-days throughout the lifecycle of the solution.

Source: pinterest.com

Source: pinterest.com

Prevention costs are one of the four elements of cost of quality. Cost of Quality is a methodology used to define and measure where and what amount of an organizations resources are being used for prevention activities and maintaining product quality as opposed to the costs resulting from internal and external failures. One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. Quality Assurance is popularly known as QA Testing. The Cost of Quality can be represented by the sum of two factors.

Source: pinterest.com

Source: pinterest.com

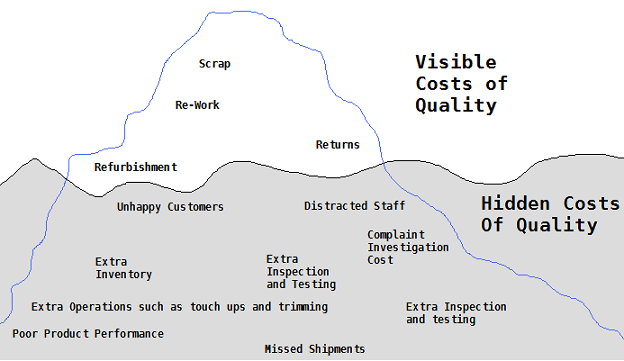

In this site the term quality costs means the cost of poor quality. Total Cost of Quality can be calculated as the sum of costs. The total cost of quality is 80 man-days while the failure cost would be reduced by 250 to 350 man-days throughout the lifecycle of the solution. Quality costs are the costs associated with preventing finding and correcting defective work. They can both be visible and hidden.

Source: pinterest.com

Source: pinterest.com

In this site the term quality costs means the cost of poor quality. There are few studies where the internal cost of implementing an ISO 9001 management system have been carefully compared against the cost of the consultant. Prevention Appraisal Internal Failure External Failure. Cost of Quality COQ Cost of quality COQ is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality that appraise the quality of the organizations products or services and that result from internal and external failures. What is Quality Cost Analysis.

Source: pinterest.com

Source: pinterest.com

The total cost of quality is 80 man-days while the failure cost would be reduced by 250 to 350 man-days throughout the lifecycle of the solution. Quality Assurance in Software Testing is defined as a procedure to ensure the quality of software products or services provided to the customers by an organization. Quality Assurance is popularly known as QA Testing. Costs and Cost Analysis Hospital Bed Capacity 300 to 499 Hospitals Community economics. This calculates out to approximately 20 per admission.

Source: pinterest.com

Source: pinterest.com

Before discussing the Cost of Quality COQ or indeed the Cost of Poor Quality COPQ we must first understand the origin of the term. Definition of quality cost as those which are incurred from investing in preventing noncompliance with requirements evaluating compliance with the requirements of a product or service and failure to meet requirements. Phil Crosby one of the fathers of quality spoke of and called his book Quality is Free. Before discussing the Cost of Quality COQ or indeed the Cost of Poor Quality COPQ we must first understand the origin of the term. The generation of a detailed documentation requires 100 man-days which would result in 0 costs of non-conformance.

Source: pinterest.com

Source: pinterest.com

One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. These costs are huge running at 20 - 40 of sales3 Many of these costs can be significantly reduced or completely avoided. Quality costs are the costs associated with preventing finding and correcting defective work. Quality assurance focuses on improving the software development process and making it efficient and effective as per the quality standards defined for software products. Management studies the costs due to defects and not the cost to prevent the defects.

Source: no.pinterest.com

Source: no.pinterest.com

There are few studies where the internal cost of implementing an ISO 9001 management system have been carefully compared against the cost of the consultant. They can both be visible and hidden. Quality costs are the costs associated with preventing finding and correcting defective work. When implement and tracking a cost of quality system within a company management typically focuses on internal and external failure costs. Total Cost of Quality can be calculated as the sum of costs.

Source: pinterest.com

Source: pinterest.com

Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses. Prevention costs are one of the four elements of cost of quality. Quality Assurance in Software Testing is defined as a procedure to ensure the quality of software products or services provided to the customers by an organization. They can both be visible and hidden. The cost of quality not only includes factory.

Source: pinterest.com

Source: pinterest.com

Costs and Cost Analysis Hospital Bed Capacity 300 to 499 Hospitals Community economics. Quality assurance focuses on improving the software development process and making it efficient and effective as per the quality standards defined for software products. 1 877 238 5855. This calculates out to approximately 20 per admission. The cost of quality not only includes factory.

Source: pinterest.com

Source: pinterest.com

One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. This calculates out to approximately 20 per admission. He famously said Do things right in the first place and you wont have to pay to fix them. Definition of quality cost as those which are incurred from investing in preventing noncompliance with requirements evaluating compliance with the requirements of a product or service and failure to meet requirements. Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses.

Source: pinterest.com

Source: pinterest.com

Prevention costs are one of the four elements of cost of quality. These costs are huge running at 20 - 40 of sales3 Many of these costs can be significantly reduced or completely avoided. He famously said Do things right in the first place and you wont have to pay to fix them. Management studies the costs due to defects and not the cost to prevent the defects. This is very important as the internal costs are often ignored probably because they are difficult to quantify.

Source: pinterest.com

Source: pinterest.com

Costs and Cost Analysis Hospital Bed Capacity 300 to 499 Hospitals Community economics. Cost of Quality is a methodology used to define and measure where and what amount of an organizations resources are being used for prevention activities and maintaining product quality as opposed to the costs resulting from internal and external failures. This is very important as the internal costs are often ignored probably because they are difficult to quantify. Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses. Costs of activities that are specifically designed to prevent poor quality which include Coding errors Design errors Mistakes in the user manuals Dadly documented or unmaintainably complex code.

Source: pinterest.com

Source: pinterest.com

He famously said Do things right in the first place and you wont have to pay to fix them. They can both be visible and hidden. Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses. Prevention costs are one of the four elements of cost of quality. Definition of quality cost as those which are incurred from investing in preventing noncompliance with requirements evaluating compliance with the requirements of a product or service and failure to meet requirements.

Source: pinterest.com

Source: pinterest.com

Normally quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses. Cost of Quality is a methodology used to define and measure where and what amount of an organizations resources are being used for prevention activities and maintaining product quality as opposed to the costs resulting from internal and external failures. They can both be visible and hidden. One of the key functions of a Quality Engineer is the reduction of the total cost of quality associated with a product. In this site the term quality costs means the cost of poor quality.

Source: pinterest.com

Source: pinterest.com

Cost of Quality is a methodology used to define and measure where and what amount of an organizations resources are being used for prevention activities and maintaining product quality as opposed to the costs resulting from internal and external failures. When implement and tracking a cost of quality system within a company management typically focuses on internal and external failure costs. Cost of Quality COQ Cost of quality COQ is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality that appraise the quality of the organizations products or services and that result from internal and external failures. Definition of quality cost as those which are incurred from investing in preventing noncompliance with requirements evaluating compliance with the requirements of a product or service and failure to meet requirements. Cost of Quality is a methodology used to define and measure where and what amount of an organizations resources are being used for prevention activities and maintaining product quality as opposed to the costs resulting from internal and external failures.